BRASS CDA464 (Naval Brass, Uninhibited)

- Stock: 1

- MPN: BRASS CDA464 (Naval Brass, Uninhibited)

Description

Naval brass is the classic marine, high-strength and corrosion-resistant alloy containing 60 percent copper, .75 percent tin and 39.2 percent zinc.

It is widely used in marine construction where strong, corrosive-resistant and hard material is required and is suitable for both salt and fresh water applications. Naval brass is used in propeller shafts, marine hardware, decorative fittings, shafting, propeller shafts and turn buckles. There are also many industrial applications, such as welding rods, condenser plates, structural uses, valve stems, balls, heat exchanger tubes, aircraft turnbuckle barrels, dies, and many more.

Naval Brass C46400 is nominally composed of 60% copper, 39.2% zinc and 0.8% tin. As is typical of brass alloys with the duplex alpha + beta structure, C46400 has good strength and rigidity. By substituting tin for an equal quantity of zinc, a high corrosion resistance to seawater is achieved. The addition of tin also gives the alloy an inherent resistance to dezincification, thereby further inhibiting the impingement by seawater at higher than normal temperatures. The alloy is also noted for its resistance to wear, fatigue, galling, and stress corrosion cracking.

Common Fabrication Processes

Blanking, Drawing, Forming and Bending, Heading and Upsetting, Hot Forging and Pressing, Hot Heading and

Upsetting, Shearing

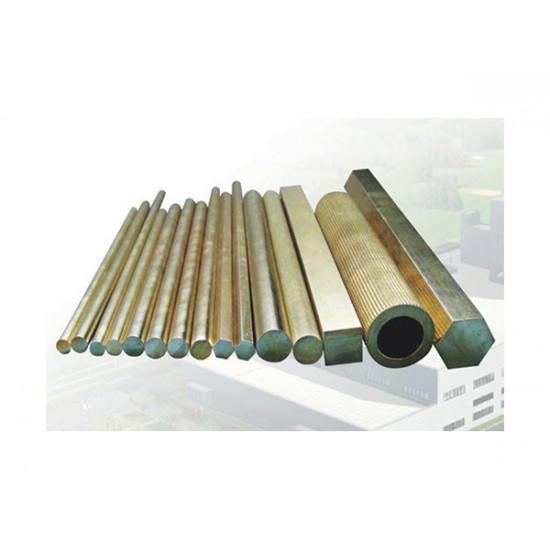

Shapes

Round, Square, Rectangular, Hexagonal, Hollow, Profile

Typical Uses

Builders Hardware

Lock Pins.

Electrical

Precision Shipboard Equipment.

Fasteners

Nuts, Rivets, Bolts.

Industrial

Structural Uses, Condenser Plates, Welding Rod, Bushings, Bearings, Valve Stems, Balls, Aircraft Turn buckle

Barrels, Heat Exchanger Tube, Hub Cones, Bearings, Dies, Golf Ball Production, and Pressure Vessels.

Marine

Propeller Shafts, Turn buckles, Shafting, Propeller Shafts, Decorative Fittings, Marine Hardware.

Ordnance

Missile Components.